Water Cooled Chiller Factory – 5KW-70KW Air Cooled Chillers Industrial Chiller – solarshine

Water Cooled Chiller Factory – 5KW-70KW Air Cooled Chillers Industrial Chiller – solarshine Detail:

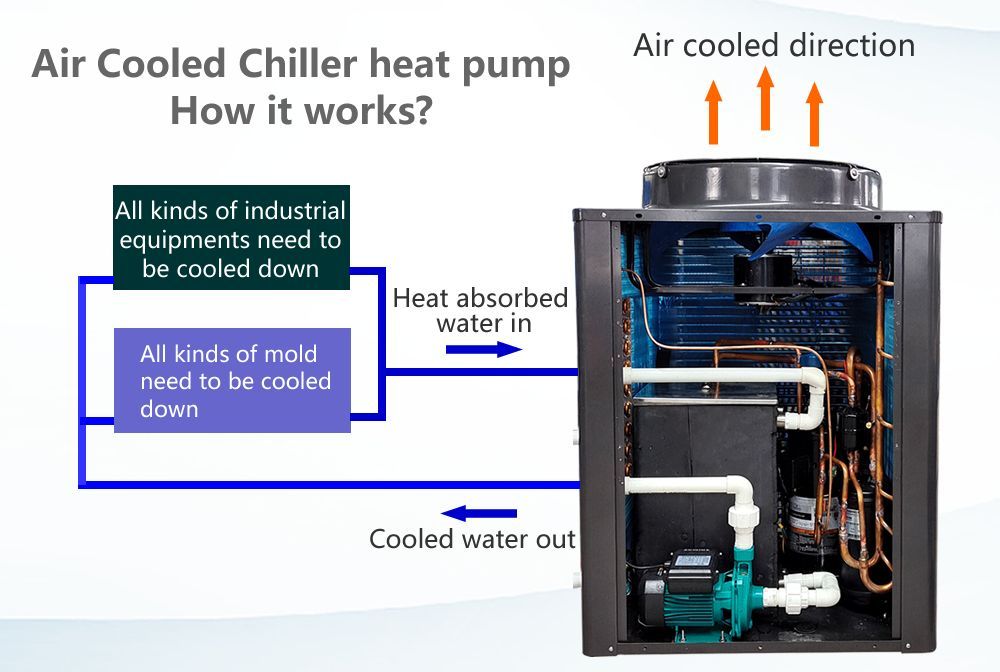

Industrial chillers are widely used for cooling industrial equipment such as machinery industry, injection molding machine, sputtering instrument, vacuum furnace, coating machine, accelerator, etc. It plays a key role in maintaining the normal operation of industrial equipment and ensuring its service life. The cooling capacity of KL series air cooled chillers ranges from 5KW to 70KW, which can fully meet the cooling needs of various industries equipment.

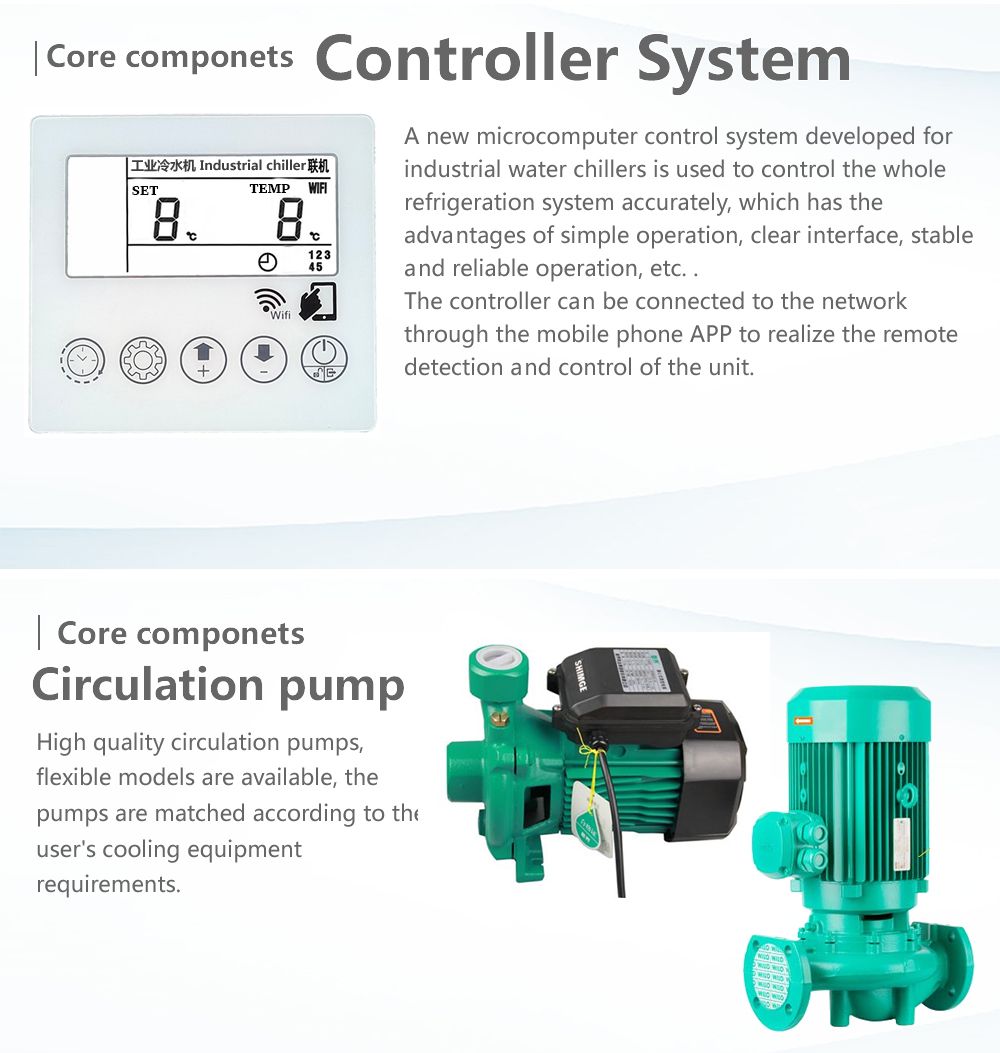

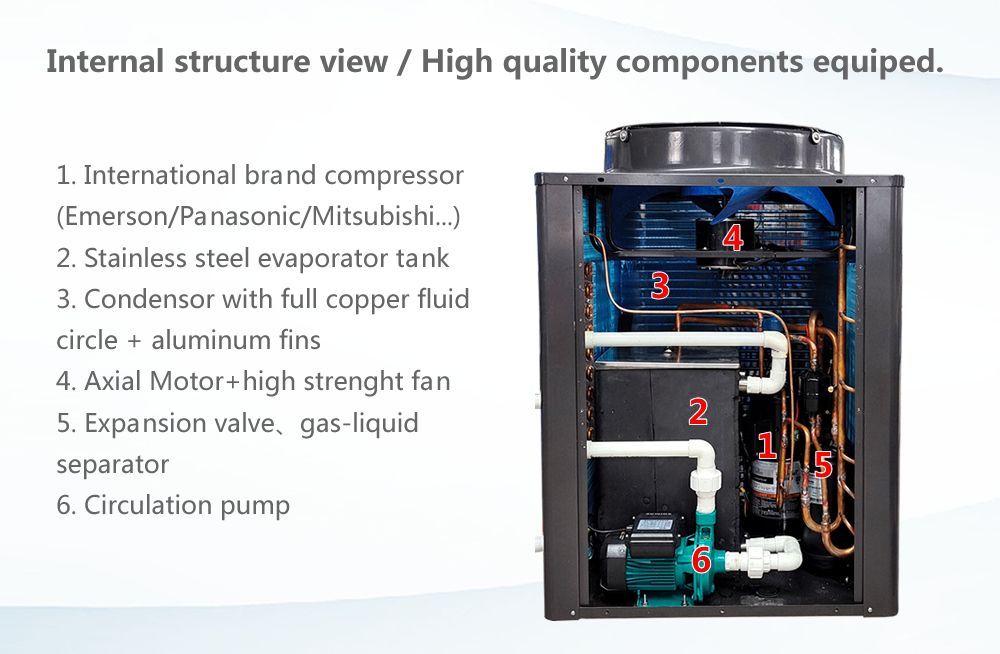

This series of SolarShine air cooled chillers use high-efficiency and energy-saving compressor, matched with high-quality condenser and evaporator, with high efficiency, stable performance, low noise and long service life. The industrial unit is centrally controlled and equipped with the energy ratio of compressor, which can timely and accurately control the matching of refrigeration capacity and cooling load of the unit, ensure the operation of the unit with the best efficiency and reduce the operation cost.

Specification

| Models | KL-2 | KL-2.5 | KL-3 | KL-4 | KL-5 | KL-6.5 | KL-7 | KL-10 | KL-12 | KL-15 | KL-20 | KL-25 | KL-30 |

| Compressor Total Power(HP) | 2 | 2.5 | 3 | 4 | 5 | 6.5 | 7 | 10 | 12 | 15 | 20 | 25 | 30 |

| Cooling Capacity(KW) | 5.1 | 6.3 | 8.4 | 9.6 | 13.5 | 16.5 | 18.6 | 27 | 33 | 37.5 | 54 | 66 | 75 |

| Input Power(KW) | 1.7 | 2.1 | 2.8 | 3.2 | 4.5 | 5.5 | 6.2 | 9 | 11 | 12.5 | 18 | 22 | 25 |

| Power Supply | 220V/50HZ | 220/380V/50HZ | 380V/3N/50HZ | ||||||||||

| Rated Water Temperature/ Min. Water Temperature |

10℃/7℃ | ||||||||||||

| Compressor | Panasonic / Mitsubishi double moto | Copeland ZW Scroll Compressor | |||||||||||

| Number of Compressors | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 4 | 4 |

| Evaporator | high efficiency coil evaporator | ||||||||||||

| Capacity of evaporation water tank(L) | 40 | 40 | 50 | 50 | 70 | 70 | 70 | 140 | 140 | 200 | 240 | 280 | 300 |

| Condenser | U Shape | U Shape | U Shape | U Shape | U Shape | U Shape | U Shape | L Shape | L Shape | V Shape | V Shape | V Shape | V Shape |

| Power(W) and Number of Fan | 90 | 90 | 250 | 250 | 250 | 250 | 250 | 250*2 | 250*2 | 550*2 | 600*2 | 630*2 | 600*3 |

| Refrigerant | |||||||||||||

| Noise(dB) | 60 | 60 | 60 | 60 | 60 | 65 | 65 | 80 | 80 | 80 | 80 | 80 | 80 |

| Cooling Water Inlet/outlet Size | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | DN50 | DN65 |

| Pump flow( m³/h) | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 7 | 8.5 | 10.5 | 18 | 21 | 21 |

| Dimensions(MM) | 695 | 695 | 760 | 760 | 760 | 760 | 760 | 1500 | 1500 | 1500 | 1850 | 2000 | 2350 |

| 655 | 655 | 690 | 690 | 690 | 690 | 690 | 690 | 690 | 690 | 1000 | 1100 | 1100 | |

| 850 | 850 | 1100 | 1100 | 1100 | 1100 | 1100 | 1080 | 1080 | 1080 | 1940 | 1920 | 1860 | |

| Weight(KG) | 76 | 80 | 90 | 95 | 120 | 130 | 135 | 280 | 290 | 360 | 560 | 600 | 680 |

| Remarks: the above refrigerating capacity parameters are the referred to chilled water inlet temperature 12 ℃, outlet temperature 7 ℃, cooling water inlet temperature 30 ℃ and outlet temperature 35 ℃. Due to the fluctuation of working conditions, the cooling capacity of the unit will fluctuate. |

|||||||||||||

SolarShine Air Cooled Chiller Details

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in high quality, be rooted on credit rating and trustworthiness for growth", will continue to serve outdated and new consumers from home and overseas whole-heatedly for Water Cooled Chiller Factory – 5KW-70KW Air Cooled Chillers Industrial Chiller – solarshine , The product will supply to all over the world, such as: Kyrgyzstan, Doha, Swaziland, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.