Solar Water Heater Pump Factories – 300L Solar Water Heater with Flat plate collector pressured type – solarshine

Solar Water Heater Pump Factories – 300L Solar Water Heater with Flat plate collector pressured type – solarshine Detail:

|

PART |

Model |

TH- 300- A4.0 |

|

1. Water Storage Tank |

Net. Capacity |

300 Liters |

|

Ext. Size(mm) |

Φ560 x 1870 |

|

|

Inner material |

SUS304 2B 1.8mm |

|

|

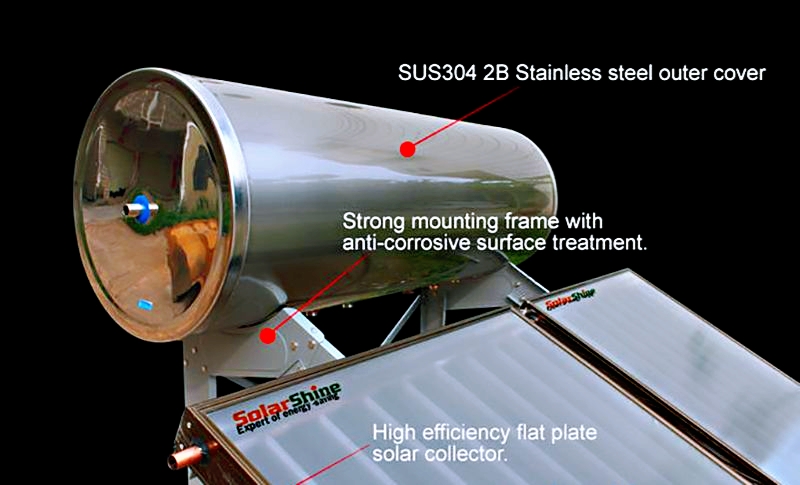

Tank out cover material |

SUS201 stainless steel |

|

|

Insulation |

High density polyurethane / 50MM |

|

|

2.Solar Collector |

Collector Model* |

C-2.0/2.4-78 solar collector (Specification see page4-7) |

|

Collector Size (mm) |

2000x1000x78 |

|

|

Collector quantity |

2 x 2M2 |

|

|

Total Collector Area |

4 M2 |

|

|

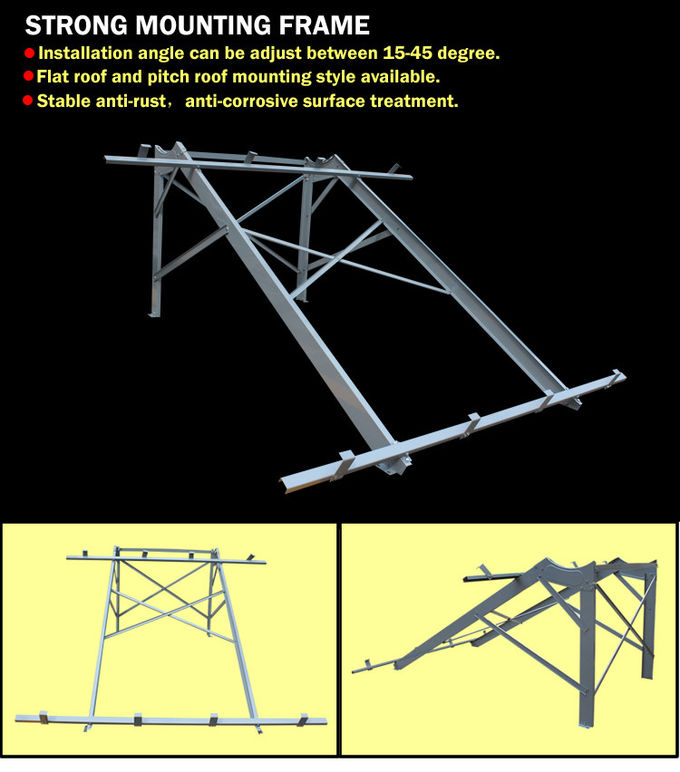

3.Mounting Stand bracket |

Aluminum alloy mounting stand for flat roof * 1SET |

|

|

4. Fitting and pipe See the picture at page 2 |

Brass fitting/ Valve / PPR circulation pipe * 1set |

|

|

5. Controller (Optional) See the picture at page 2 |

Full automatic intelligent system controller * 1ET |

|

|

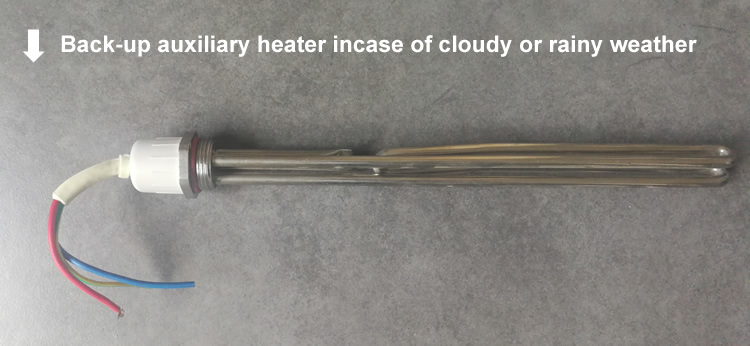

6. Auxiliary Electric Heater(Optional) See the picture at page 2 |

3KW |

|

|

20’ container loading quantity |

25 Sets |

|

What is thermosiphon system?

Thermosiphon system is passive with a solar hot water storage tank mounted higher than the solar collector. They rely on passive natural convection where cold water falls, moving hot water to the storage reservoir at the top, that means cold water pushes up the hot water. The advantage of this system is that there are no moving parts, which means you almost don’t need maintenance.

The features of the solar tank:

1. The inner tank is made of stainless steel 304, with good tensile performance, can bear high pressure.

2. Foaming insulation material: polyurethane material, fluorine- free, environmental protection, excellent thermal insulation effect.

3. Color steel plate: various colors available, high strength, corrosion resistance, no fading and no paint stripping.

4. Coil: high quality 316L stainless steel pipe, can withstand 12.5mpa pressure, ultra-high pressure bearing capacity, ultra- high corrosion resistance, double- layer and three-layer winding design, excellent heat exchange effect.

The features of the solar collectors:

1. Glass- low iron, cloth, tempered glass.

3.2mm high-quality low iron tempered glass: the “core” with full spectrum transmittance of 91.7% and no fading.

2 Black chrome selective coating , high efficiency.

3. Heat transfer structure- optimizing structure and strengthening heat transfer.

All copper tube runner design, pollution-free, high pressure bearing, good heat transfer performance.

4. Mechanical properties: weather resistance, corrosion resistance and pressure resistance

Weather resistance: the coating is stable and suitable for various adverse weather conditions:

Corrosion resistance: high temperature (480c) oxidation / hardening treatment on the alloy surface makes it has better corrosion resistance and pressure resistance than copper: the pressure bearing design and welding process of 35PA flow channel structure ensure the service life of the collector for 30 years:

5.Thermal performance – high efficiency and low heat loss.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Solar Water Heater Pump Factories – 300L Solar Water Heater with Flat plate collector pressured type – solarshine , The product will supply to all over the world, such as: Slovakia, Vancouver, Thailand, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.