China High Quality Domestic Heat Pump Systems – 400L Air Source Heat Pump Water Heater – solarshine

China High Quality Domestic Heat Pump Systems – 400L Air Source Heat Pump Water Heater – solarshine Detail:

Description of SolarShine Heat Pump Water Heater

|

Storage / Tankless |

Source |

Housing Material |

Galvanized Sheet |

|

Use |

Bathroom, family house |

Heating Capacity |

5KW |

|

Refrigerant |

R410a, R417a/R410A |

Compressor |

Copeland, Copeland Scroll Compressor |

|

Voltage |

220V 〜lnverter |

Power Supply |

220V/ 380V |

|

High Light |

cold temperature heat pump, inverter air source heat pump |

Cop |

4.0 |

|

Heat Exchanger |

Shell Heat Exchanger |

Sound Level |

52db ( 1m ) |

|

Working Ambient Temperature |

-7~+43 Deg C |

Compressor Type |

Copeland Scroll Compressor |

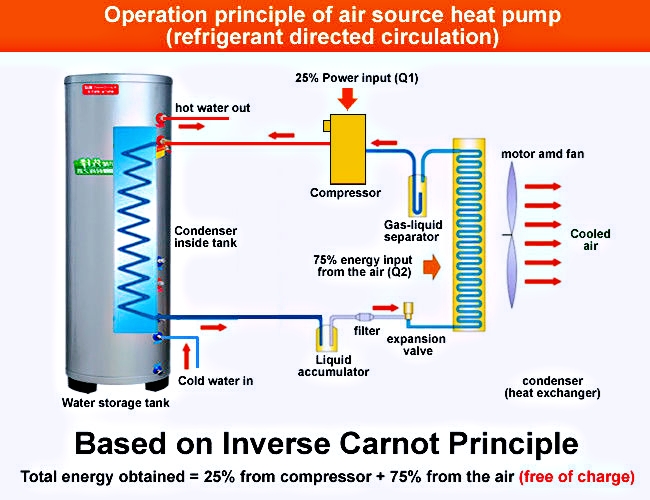

Working principle of condenser:

Condenser is a part of refrigeration system and belongs to a kind of heat exchanger. It can convert gas or steam into liquid and quickly transfer the heat in the pipe to the air near the pipe. The gas passes through a long tube (usually coiled into a solenoid) so that heat is dissipated into the surrounding air. Copper and other metals have strong thermal conductivity and are often used to transport steam. In order to improve the efficiency of the condenser, a radiator with excellent thermal conductivity is often installed on the pipeline to increase the heat dissipation area, accelerate the heat dissipation, and accelerate the air convection through the fan to take away the heat. The working process of the condenser is exothermic, so the temperature of the condenser is relatively high.

Working principle of evaporator:

Evaporator is a very important part of air to water heat pump. The low-temperature condensed “liquid” (refrigerant) after compression and liquefaction passes through the evaporator to exchange heat with the outside air, and “gasification” absorbs heat to reduce the temperature of the surrounding medium, so as to achieve the refrigeration effect.

Specification of SolarShine Heat Pump Water Heater

| Specification details | |||||||

| Product type | Water circulation type air source heat pump water heater (Pressurized) | ||||||

| MODEL | S-150L-1HP | S-200L-1HP | S-250L-1.5HP | S-300L-1.5HP |

S-400L-2HP |

S-500L-2HP | |

|

Water Tank |

Water Tank Volume | 150 Liters | 200 Liters | 250 Lit res | 300 Lit res | 400 Lit res | 500 Lit res |

| Water Tank Size(MM) | ①470*1545 | <P520*1545 | 中560*1625 | 0)560*1915 | ①700*1625 | 0)700*1915 | |

| Water Tank outer cover | Colorful shining steel(with anti-corrosive surface treatment, white / golden / Silver available) | ||||||

| Water Tank inner cylinder and wall thickness | SUS304/1.0mm | SUS304/1.2mm | SUS304/1.5mm | SUS304/1.5mm | SUS304/1.5mm | SUS304/1.5mm | |

| Heat Exchanger | N/A | ||||||

| Insulation | 50mm high density polyurethane | ||||||

| Rated Working Pressure | 0.6Mpa | ||||||

|

Heat Pump Main Unit |

Main unit power (HP) | 1Hp | 1Hp | 1.5Hp | 1.5Hp | 2Hp | 2Hp |

| Power consumption | 1KW | 1KW | 1.32KW | 1.32KW | 1.32KW | 1.67KW | |

| Nominal Heating capacity | 3.5KW | 3.5KW | 4.73KW | 4.73KW | 4.73KW | 6.5KW | |

| Fluid pressure reduce and adjustment device | Electronic Expansion Valve | ||||||

| Ext. Dimension(mm) | 756 x 260 x 450 | 920 x 280 x 490 | |||||

| Power Supply | AC220V/50hz | ||||||

| Refrigerant | R410A/R407C (new environmental refrigerant) | ||||||

| 20,container loading quantity | 60 sets | 40 sets | 38 sets | 32 sets | 25 sets | 20 sets | |

Low pressure gaseous refrigerant enters the compressor and is compressed into high temperature and high pressure gas. At this time, the boiling point of the refrigerant increases with the increase of pressure. The refrigerant with high boiling point enters the condenser and begins to liquefy. At this time, the refrigerant releases heat and becomes liquid. Then, before entering the evaporator, it passes through the expansion valve (throttle valve) to reduce the pressure of the refrigerant, and the reduced refrigerant begins to evaporate in the evaporator. At this time, the refrigerant absorbs heat and becomes a low-pressure gas again. Enter the compressor again to form the whole refrigerant circulation system.

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for China High Quality Domestic Heat Pump Systems – 400L Air Source Heat Pump Water Heater – solarshine , The product will supply to all over the world, such as: Durban, Thailand, Manila, We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.