China High Quality Commercial Heat Pump System Manufacturer – 3Hp-30Hp Medium and Big Size Air Source Heat Pump for Central Hot Water System – solarshine

China High Quality Commercial Heat Pump System Manufacturer – 3Hp-30Hp Medium and Big Size Air Source Heat Pump for Central Hot Water System – solarshine Detail:

| Detailed Product Description | |||

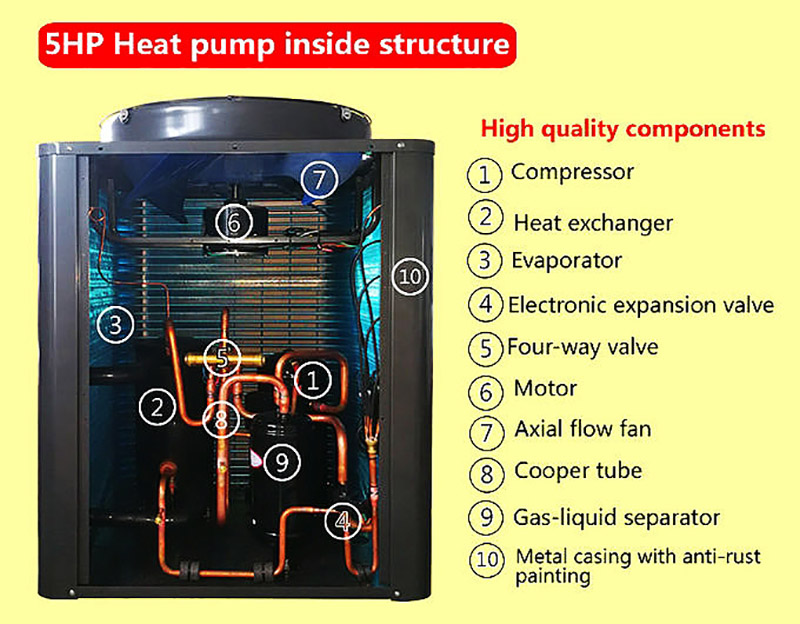

| Type: | Air Source Heat Pump | Storage/ Tankless: | Circulation Heating |

| Heating Capacity: | 4.5-20KW | Refrigerant: | R410a/ R417a/ R407c/ R22/ R134a |

| Compressor: | Copeland,Copeland Scroll Compressor | Voltage: | 220V 〜Inverter,3800VAC/50Hz |

| Power Supply: | 50/ 60Hz | Function: | House Heating,Space Heating & Hot Water,Pool Water Heating,cooling And DHW |

| Cop: | 4.10-4.13 | Heat Exchanger: | Shell Heat Exchanger |

| Evaporator: | Gold Hydrophilic Aluminum Fin | Working Ambient Temperature: | Minus 5C- 45C |

| Compressor Type: | Copeland Scroll Compressor | Color: | White,Grey |

| High Light: most efficient air source heat pump,large heat pump | |||

How much cost a heat pump can save?

During the heat pump heating water, the heat pump unit only consumes about 30% of the energy (electricity) depends on the ambient air temperature, but at the same time, it can absorb and transfer about 70% free energy (heat) from the air, so compared with traditional electric water heater, the air source heat pump water heater can save about 70% power consumption, that means it can save about 70% heating cost for us.

As cutting down carbon emission and reducing energy bills are very important, many commercial or industrial hot water projects are trying to apply heat pump to reach a long term cost saving solution. Medium and big heat pumps have been used more and more for commercial and other non-domestic sites, by installing the air source heat pump, this cost saving strategy can last 10- 25 years or longer.

How to size the heat pump I need?

Step 1: First how to calculate the water you need? There is one principle can be follow, take a hotel for example: normally one persons need 50Liters hot water each day, if you have a small hotel for 10 rooms, each room receive 2 person per day, then one day you need 50x 10 x 2 = 1000Liters.

size the heat pump you need. See the follow pictures please:

|

1500L |

3Hp |

|

2000L-3000L |

4Hp |

|

3000L-4000L |

5Hp |

|

4000L-5000L |

6.5Hp-7Hp |

|

5000L-6000L |

7Hp |

|

6000L-8000L |

7Hp-10Hp |

Features:

• High- efficiency, Maximum up to 75% energy saving, compared with conventional water heaters such as gas/oil boilers and electricity water heaters.

• Economical, less running cost, only consume a little energy for the compressor working.

• Eco-friendly, no exhaust gas, no waste water drained to harm environments.

• Powder coated steel plate cabinet (stainless steel cabinet available).

• 24 hours timer clock, no human attendance is required.

|

Model |

KGS-3 |

KGS-4 |

KGS-5-380 |

KGS-6.5 |

KGS-7 |

KGS-10 |

KGS-12 |

KGS-15 |

||

|

Input Power(KW) |

2.8 |

3.2 |

4.5 |

5.5 |

6.3 |

9.2 |

11 |

13 |

||

|

Heating power(KW) |

11.5 |

13 |

18.5 |

33.5 |

26 |

38 |

45 |

53 |

||

|

Power Supply |

220/ 380V |

380V/3N/50Hz |

||||||||

|

Rated water temperature |

55°C |

|||||||||

|

Max Water Temperature |

60°C |

|||||||||

|

Circulation fluid M³/H |

2-2.5 |

2.5-3 |

3-4 |

4-5 |

4-5 |

7-8 |

8-10 |

9-12 |

||

|

Compressor quantity(SET) |

1 |

1 |

1 |

1 |

1 |

2 |

2 |

2 |

||

|

Ext. Dimension |

L |

695 |

695 |

706 |

706 |

706 |

1450 |

1450 |

1500 |

|

|

W |

655 |

655 |

786 |

786 |

786 |

705 |

705 |

900 |

||

|

H |

800 |

800 |

1000 |

1000 |

1000 |

1065 |

1065 |

1540 |

||

|

N.W(KG) |

80 |

85 |

120 |

130 |

135 |

250 |

250 |

310 |

||

|

Refrigerant |

R22 |

|||||||||

|

Connection |

DN25 |

DN40 |

||||||||

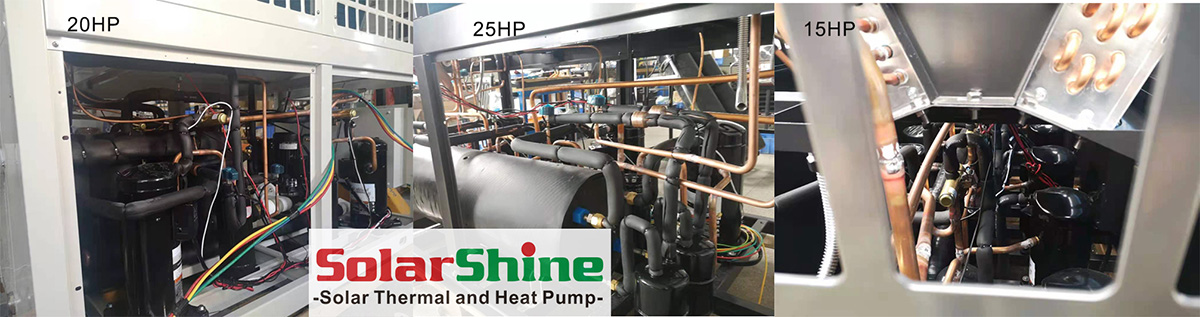

Application Cases

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for China High Quality Commercial Heat Pump System Manufacturer – 3Hp-30Hp Medium and Big Size Air Source Heat Pump for Central Hot Water System – solarshine , The product will supply to all over the world, such as: Roman, Danish, Tunisia, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.