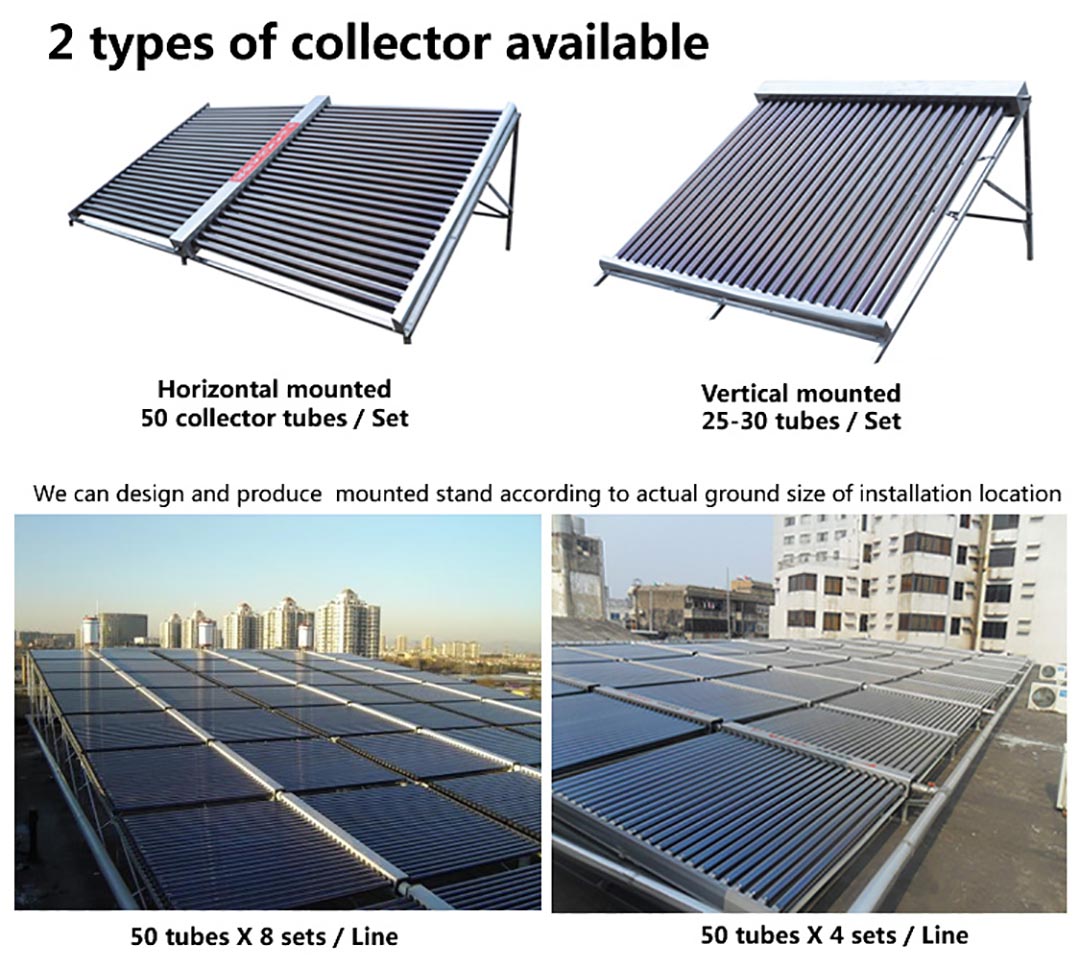

50 Tubes Vacuum Tube Solar Collector Kit Vertical Mounted

| Basic Info. | |

| Trademark | 0EM/SolarShine |

| Specification | 2000X1 000x78mm |

| HS Code | 84199010 |

| Transport Package | Standard Export Packing |

| Origin | China |

Evacuated tube solar collectors (also called vacuum tube solar collectors) are higher efficiency solar collector, simpler installation and lower cost than traditional flat plate solar collector. It is widely used in solar central hot water engineering system, and they are the central part of Solar Water Heater, they convert sun energy into thermal heat via the vacuum tubes.

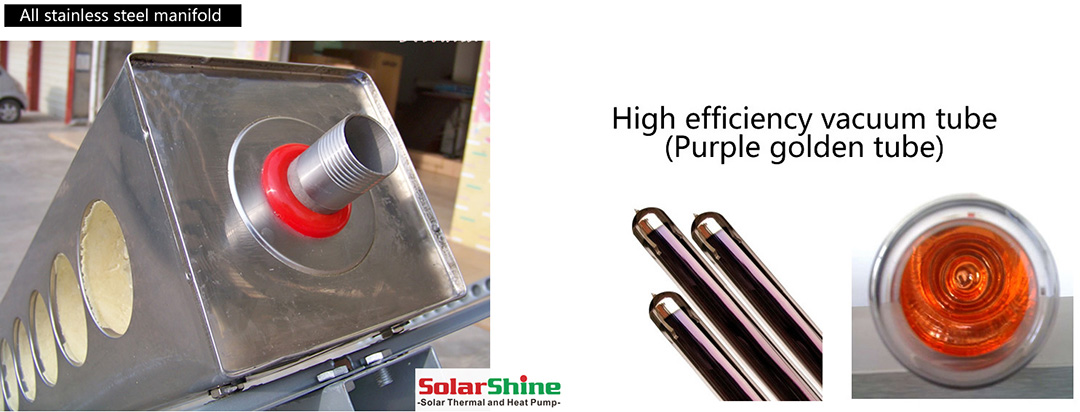

SolarShine’s Evacuated tube solar collector are Φ 58 * 1800 high efficiency collector vacuum tubes with all- glass double- tube co- axial structure.

1. Lightweight manifold design;

2. Manifold header, internal SUS 304, external SUS202;

3. Manifold has 6 has brazing joints, ensure reliable;

4. Frame Materials: Stainless Steel or anodized aluminum alloy;

5.Polyurethane insulation for high temperature stability;

6. Long use life with stability even under bad weather conditions or seaside regions;

7. Harsh UV radiation.

| Regular models specification | |||||

| ModevCapacity | 25 | 50 | 100 | 150 | 200 |

| Vacuum tube | 58*1800 high efficiency callector vacuum tubes | ||||

| vacuum tubes quantity | 25PGs | 5oPcs | 1D0Pcs | 150PcS | 2oDPcs |

| Mounted directian | Vertical | Harizantal | |||

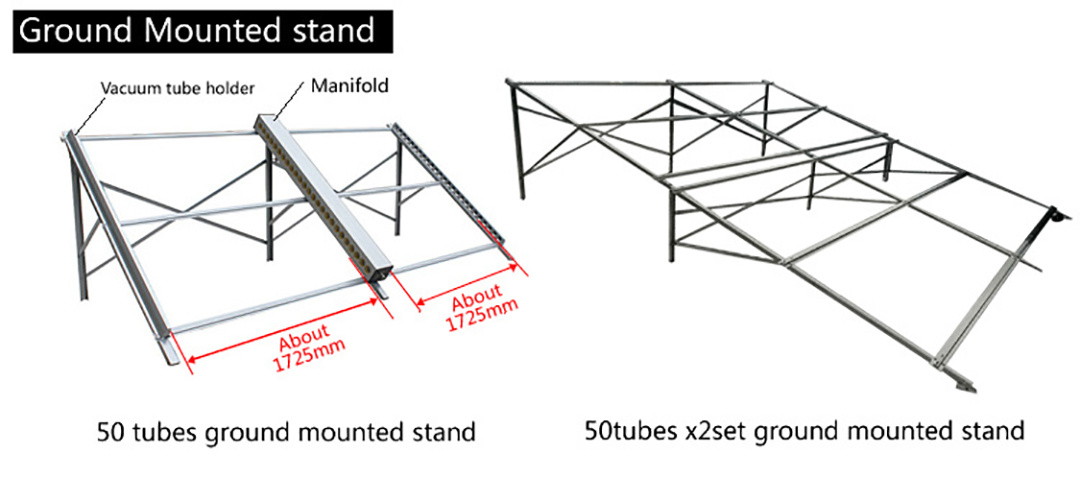

| lnstallatian size need for ground |

2X1.65 | 3.8X1.85 | 3.8X4.2 | 3.8X6.2 | 3.8X8.2 |

| Manifold inside material | sus304 2日/31BL(Optional) | ||||

| Manifold Outer cover | Stainless steel / Colorful painted steel | ||||

| lnsulation | High density polyurethane foam (Non-CFC) | ||||

| Ground stand | All stainless steel stand | ||||

| Specification of vacuum tube | |

| Structure | All- glass double- tube co- axial structure |

| Glass Material | High borosilicate glass 3.3 |

| External Pipe Diameter & Thickness | Ø= 58 ± 0.7mm & = 1.6mm, |

| Internal Pipe Diameter & Thickness | Ø= 47 ± 0.7mm & = 1.6mm, |

| Pipe Length | 1800mm |

| Coating Layers | Cu/ SS- ALN (H) /SS- ALN (L)/ ALN |

| Coating Method | Three target magnetron sputtering plation |

| Specific Absorption | as= 0.93 ~ 0.96 (AM1.5) |

| Emission Ratio | Σh= 0.04 ~ 0.06 (80°C ± 5°C) |

| Vacuum Tightness | P≤ 5.0×10- 3Pa |

| Idle Sunning Property Parameters | Y= 260 ~ 300m². °C/KW |

| Solar Radiation for Obtaining a | H≤ 3.7 MJ/ m² (Ø47), H=2.9 ~ 3.2 MJ/ m²; |

| Preset Water Temperature | H≤ 4.7 MJ/ m²(Ø58), H= 3.7 ~ 4.2 MJ/ m². |

| Average Heat Loss Coefficient | ULT= 0.4 ~ 0.6W/ (m². °C) |

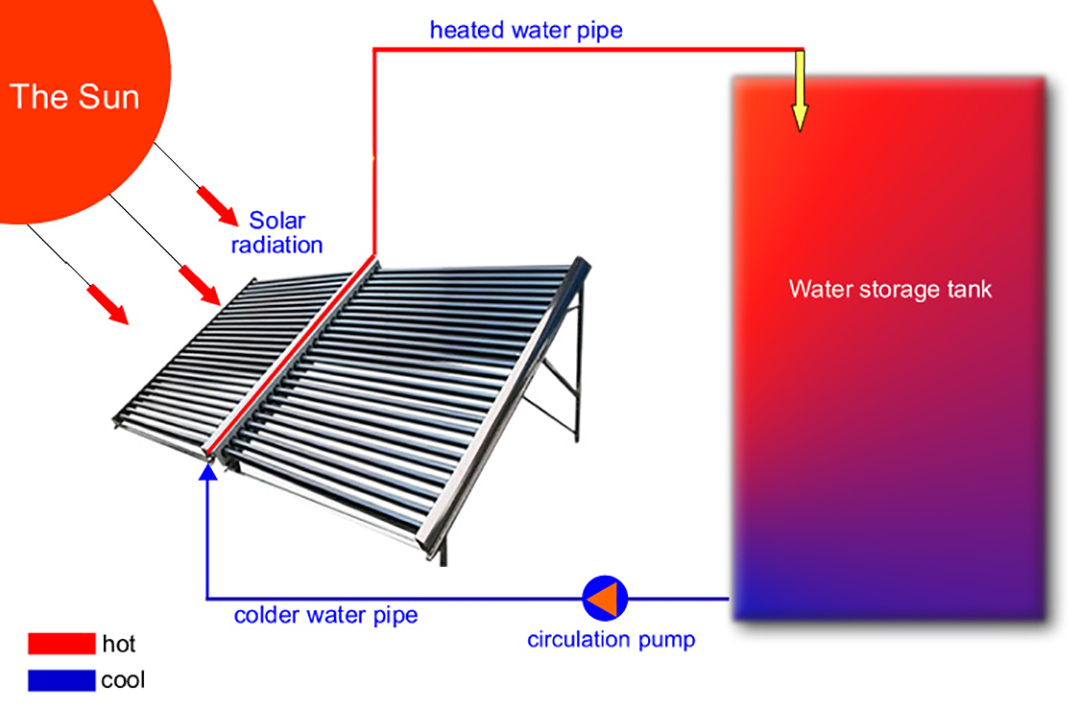

The solar radiation passes through the outer tube of the vacuum tube and is absorbed by the heat collection coating, to heat the cold water in the vacuum tube. Due to the physical characteristics of water, the density of hot water is lower than cold water, and the water will "move" in the vacuum tube. The cold water will slowly come in, and the hot water will slowly go out and enter the insulation barrel.

With the extension of radiation time, the heat will increase, the water temperature will rise, and there will be more and more hot water.

With the continuous upward movement of hot water and stored in the solar hot water tank, the water with lower temperature is continuously supplemented along the other side of the pipe. In this cycle, the whole tank of water finally rises to a certain temperature.

To save cost, a proper design and piping of the solar installation is the key for a successful solar project, it should have the features of the highest efficiency, the lowest cost and the possibility of fastest return on investment.

You may learn our design cases for your projects reference, or contact with our technical team to get more information.