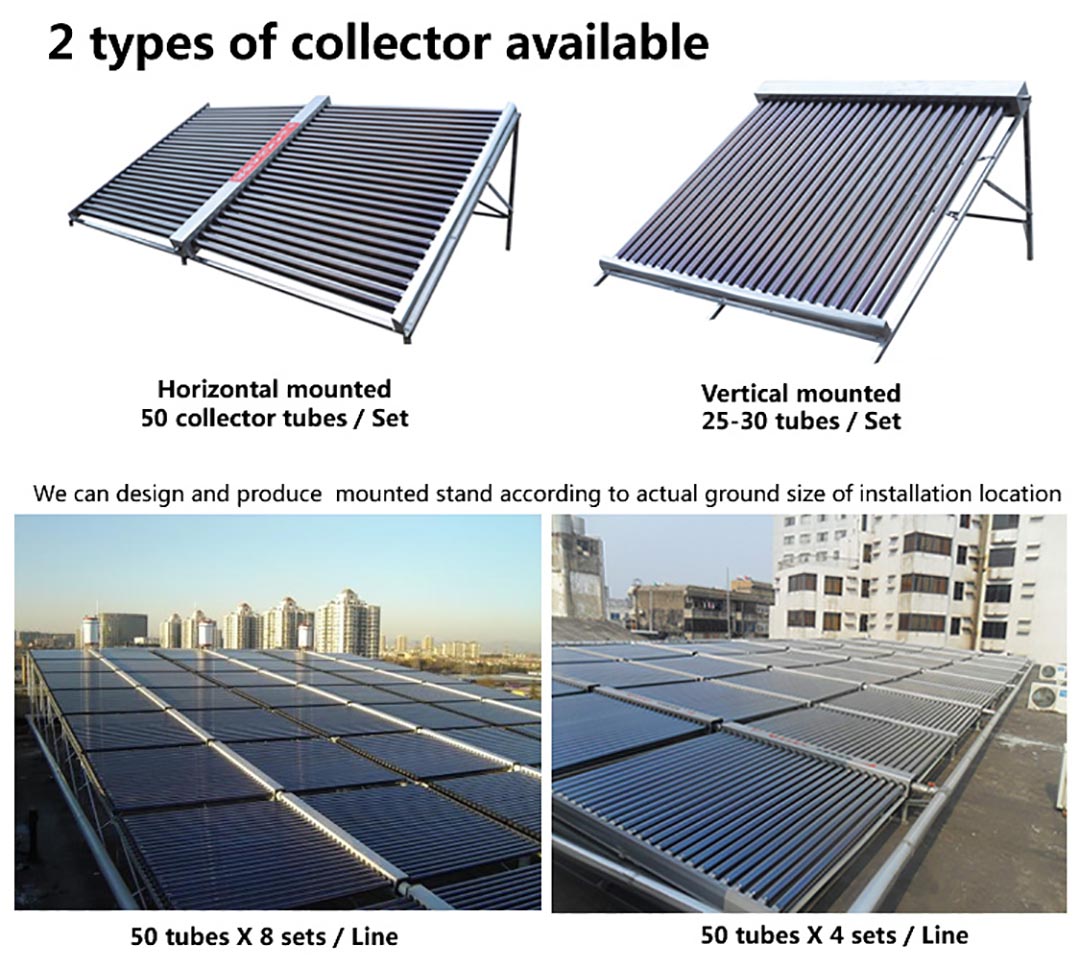

25-30 Tubes Evacuated Tube Solar Collector Kit Horizontal Mounted

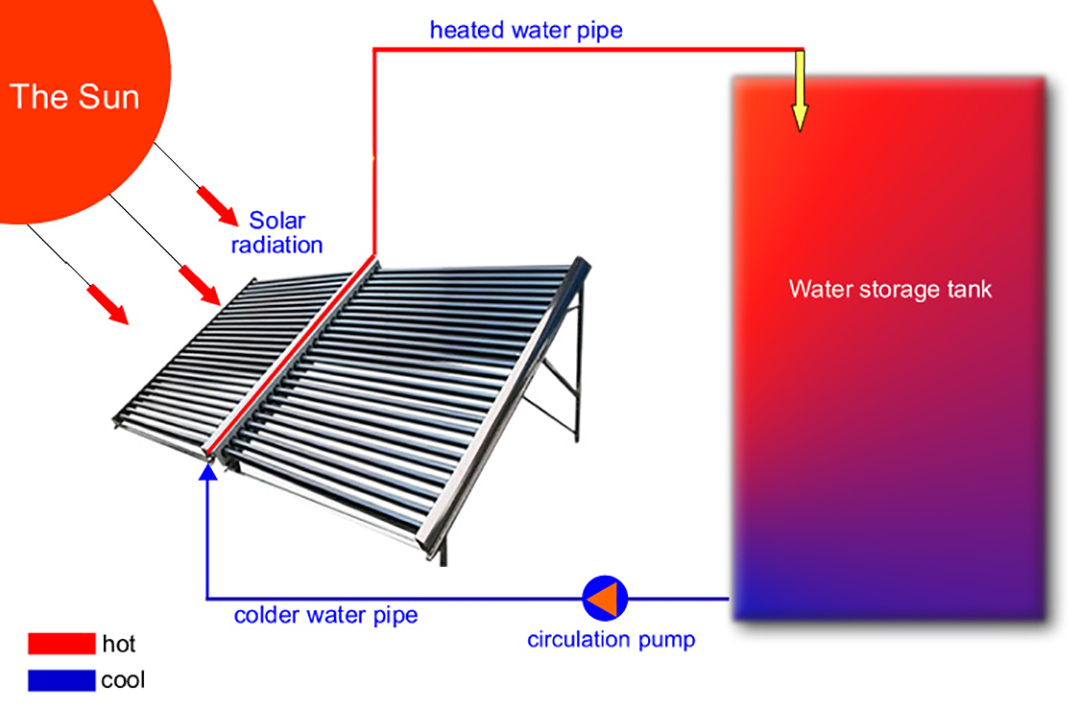

Evacuated tube solar collectors (also called vacuum tube solar collectors) are higher efficiency solar collector, simpler installation and lower cost than traditional flat plate solar collector. It is widely used in solar central hot water engineering system , and they are the central part of Solar Water Heater, they convert sun energy into thermal heat via the vacuum tubes.

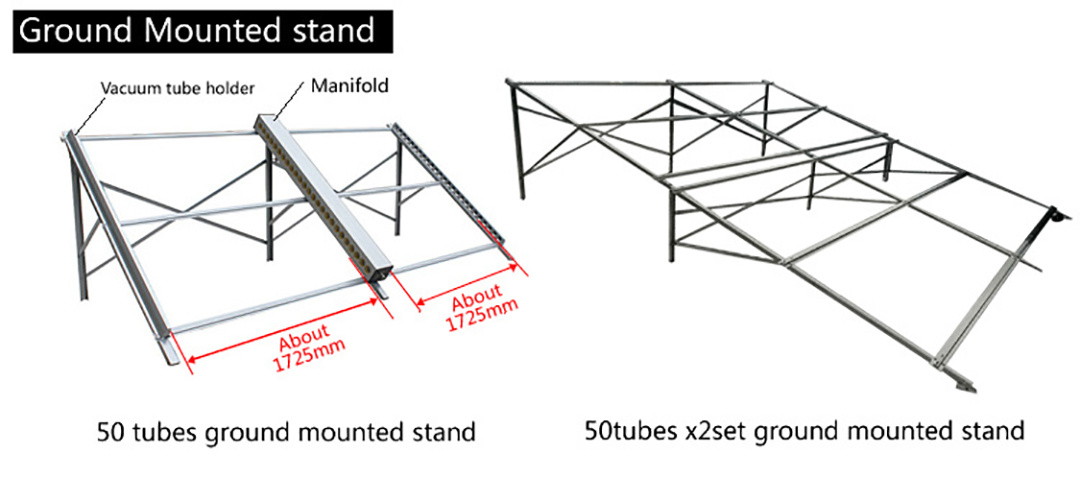

The design of the vacuum tube solar collector is very flexible. It can be used to make the appropriate support and installation method according to the installation size of different building roofs. We can design and produce mounted stand according to actual ground size of installation location for you.

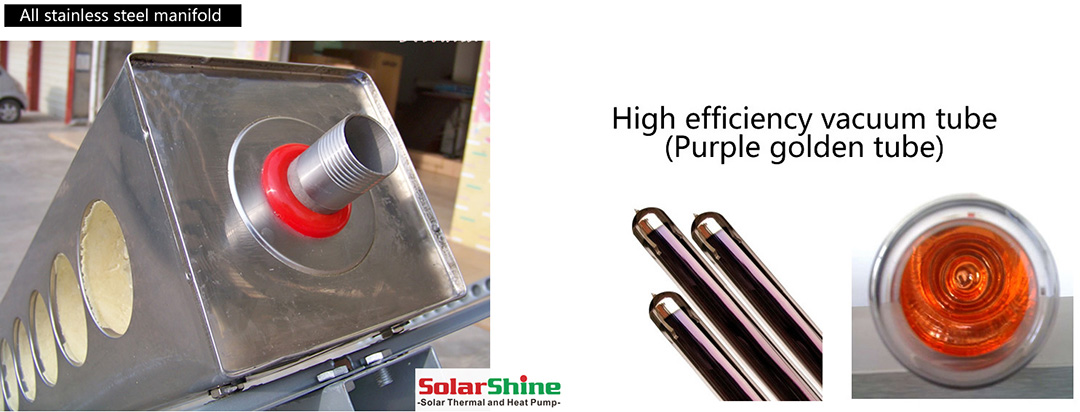

SolarShine’s Evacuated tube solar collector are Φ58 * 1800 high efficiency collector vacuum tubes with all- glass double- tube co- axial structure.

| specification of vacuum tube | |

| Structure | All- glass double- tube co- axial structure |

| Glass Material | High borosilicate glass 3.3 |

| External Pipe Diameter & Thickness | Ø= 58 ± 0.7mm & = 1.6mm, |

| Internal Pipe Diameter & Thickness | Ø= 47 ± 0.7mm & = 1.6mm, |

| Pipe Length | 1800mm |

| Coating Layers | cu/ SS-ALN (H) / SS-ALN (L) / ALN |

| Coating Method | Three target magnetron sputtering plation |

| Specific Absorption | as= 0.93- 0.96 (AM1.5) |

| Emission Ratio | zh= 0.04 ~ 0.06 (80°C+5°C) |

| Vacuum Tightness | P< 5.0×10- 3Pa |

| ldle Sunning Property Parameters | #ERROR! |

| Solar Radiation for Obtaining a | Hs3.7 MJ/ m (D47), H= 2.9 ~ 3.2 MJ m; |

| Preset water Temperature | HS4.7 MJ/ m (58), H= 3.7 ~ 4.2 MJ/ m?. |

| Average Heat Loss Coefficient | ULT= 0.4 ~ 0.6w (m?.RC) |

| Regular models specification | |||||

| ModevCapacity | 25 | 50 | 100 | 150 | 200 |

| Vacuum tube | 58*1800 high efficiency callector vacuum tubes | ||||

| vacuum tubes quantity | 25PGs | 5oPcs | 1D0Pcs | 150PcS | 2oDPcs |

| Mounted directian | Vertical | Harizantal | |||

| lnstallatian size need for ground |

2X1.65 | 3.8X1.85 | 3.8X4.2 | 3.8X6.2 | 3.8X8.2 |

| Manifold inside material | sus304 2日/31BL(Optional) | ||||

| Manifold Outer cover | Stainless steel / Colorful painted steel | ||||

| lnsulation | High density polyurethane foam (Non-CFC) | ||||

| Ground stand | All stainless steel stand | ||||

To save cost, a proper design and piping of the solar installation is the key for a successful solar project, it should have the features of the highest efficiency, the lowest cost and the possibility of fastest return on investment.

You may learn our design cases for your projects reference, or contact with our technical team to get more information.

all- glass double- tube Horizontal Mounted; mounting bracket; manifold; Assembling accessories such aluminium frame & pipe holder.