10HP Low Ambient Temperature Heat Pump

|

Type |

Low Ambient Temperature Air Source Heat Pump |

Housing Material |

Plastic, galvanized Sheet |

|

Storage / Tankless |

Circulation Heating |

Installation |

Freestanding, Wall Mounted / Freestanding |

|

Use |

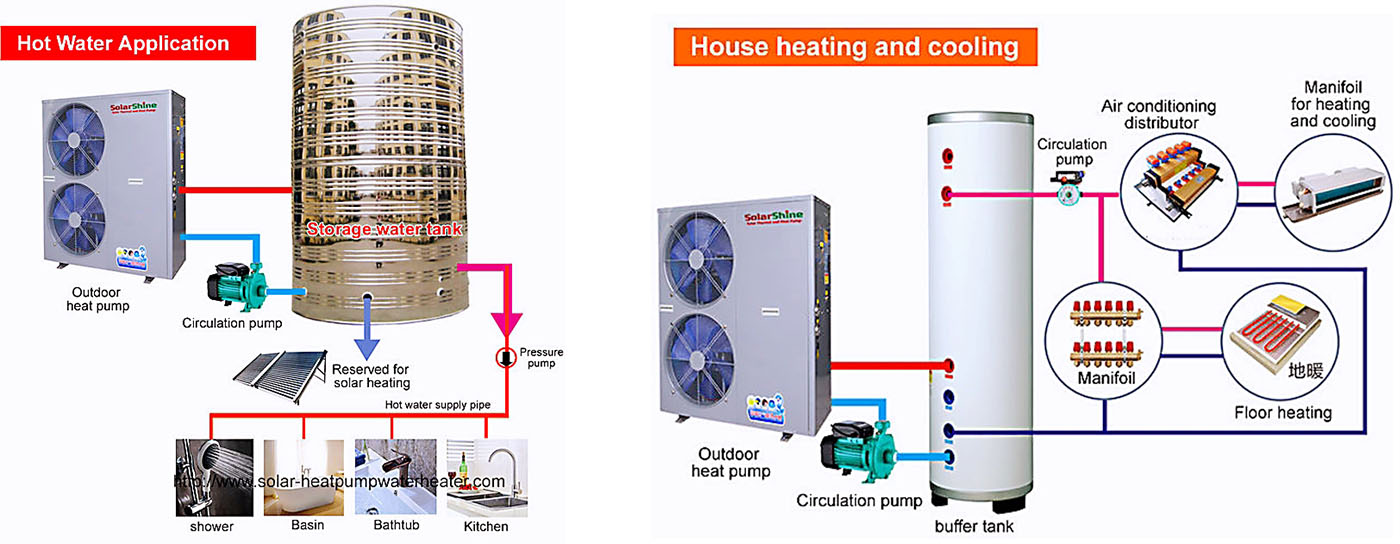

Hot Water/floor Heating/ fancoil Heating And Cooling |

Heating Capacity |

4.5-20KW |

|

Refrigerant |

R410a/ R417a/ R407c/ R22/ R134a |

Compressor |

Copeland, Copeland Scroll Compressor |

|

Voltage |

220V 〜lnverter,3800VAC/50Hz |

Power Supply |

50/ 60Hz |

|

Function |

House Heating, Space Heating & Hot Water,Pool Water Heating, cooling And DHW |

Cop |

4.10-4.13 |

|

Heat Exchanger |

Shell Heat Exchanger |

Evaporator |

Gold Hydrophilic Aluminum Fin |

|

Working Ambient Temperature |

Minus -25C- 45C |

Compressor Type |

Copeland Scroll Compressor |

|

Color |

White, Grey |

Application |

Jacuzzi Spa/ Swimming Pool,Hotel, Commercial And Industrial |

|

Input Power |

2.8-30KW |

High Light |

cold temperature heat pump, inverter air source heat pump |

What’s the working principle of low ambient temperature air source heat pump?

The heat pump unit is a closed system composed of evaporator, condenser, compressor and expansion valve, which is filled with an appropriate amount of refrigerant.

The basic principle of heat pump operation is based on the principle of reverse Carnot cycle: the liquid refrigerant first absorbs the heat in the air in the evaporator and evaporates to form steam (vaporization), and the vaporization latent heat is the recovered heat. Then it is compressed into high-temperature and high-pressure gas by the compressor and enters the condenser to condense into liquid (liquefaction) to send the absorbed heat to the required heated pool water, The liquid refrigerant returns to the expansion valve after depressurization and expansion through the expansion valve, absorbs heat and evaporates to complete a cycle. In this way, it continuously absorbs the heat of the low-temperature source and outputs the heated swimming pool water to directly reach the predetermined temperature.

|

Model |

KDR-03 |

KDR-05S |

KDR-05-G |

KDR-07-G |

KDR-10-G |

KDR-15 |

KDR-20 |

KDR-25 |

|

|

HP |

3 HP |

5 HP |

5 HP |

7HP |

10HP |

15HP |

20HP |

25HP |

|

|

Power supply |

220V/380V |

220V |

380V |

380V |

380V |

380V |

380V |

380V |

|

|

Input power |

2.8 |

4.2 |

4.7 |

5.2 |

9.2 |

13 |

18.5 |

20.5 |

|

|

Heating power output at different ambient tem. |

(20℃) |

10.8 |

16.2 |

18 |

20 |

35.4 |

50 |

71.2 |

78.9 |

|

(6/7℃) |

9 |

13.7 |

15.3 |

16.9 |

30 |

42.3 |

60 |

66.6 |

|

|

(-6/7℃) |

6.9 |

10.3 |

11.5 |

12.7 |

22.5 |

319 |

453 |

50.2 |

|

|

(-15℃) |

5.9 |

8.8 |

9.9 |

10.9 |

19.3 |

273 |

38.9 |

43 |

|

|

(-20℃) |

5.2 |

7.8 |

8.7 |

9.6 |

17 |

24 |

34.2 |

37.9 |

|

|

Cooling power output |

8.0 |

12.0 |

13.4 |

14.8 |

26.2 |

37.1 |

52.7 |

68.4 |

|

|

Fan outlet direction |

Side |

Side |

Side |

Side |

Side |

Side |

Top |

Top |

|

|

V\faler connection |

DN25 |

ON25 |

DN25 |

DN25 |

DN32 |

DN40 |

DN50 |

DN50 |

|

|

Fluid rate(M3/H) |

2-3 |

4-5 |

5-6 |

5-7 |

7-10 |

12-15 |

15-20 |

20-25 |

|

|

Dimen -sion |

(MM) |

1152 |

1190 |

1190 |

1190 |

1350 |

1350 |

1800 |

1800 |

|

(MM) |

422 |

425 |

425 |

425 |

645 |

645 |

1100 |

1100 |

|

|

(MM) |

768 |

1240 |

1240 |

1240 |

1845 |

184S |

2100 |

2100 |

|

|

WEIGHT (kg) |

130 |

180 |

160 |

220 |

310 |

355 |

630 |

780 |

|

Compared with ordinary heat pumps, at - 10 ℃ and lower temperatures, the evaporation temperature is too low, resulting in less evaporation, resulting in less return air volume of the compressor, which affects the condensation and heat release. An injection enthalpy increasing branch connecting the compressor is added to the ultra low ambient temperature heat pump. When the return air of the compressor is insufficient, the injection enthalpy increasing branch will make up air for the compressor, so the heat release of the condenser will be increased, so it can still produce heat normally at very low temperature.